National Ready Mixed Concrete Co. links leadership in low carbon mixes to business growth. Increases market presence with green building expertise, digital EPD technology, portland-limestone cement and a growing RNG-fueled fleet.

BY DON MARSH

and construction phase carbon reductions. PLANT, SITE PHOTOS: Gus Ruis, National Ready Mixed Concrete Co.

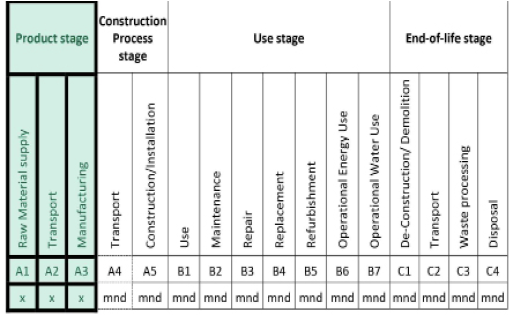

Development of credible accounting methods for all carbon dioxide emissions attributable to fresh and finished concrete is a marathon whose course tracks the Raw Materials, Transport, Manufacturing phases or Product Stage, plus Construction Process, Use and End of Life Stages. Environmental product declarations (EPD)—the baseline tool for carbon-minded architecture, engineering and construction interests—offer credible verified accounting for the first three stages. Top of mind for AEC professionals reviewing a concrete EPD is the “global warming potential” metric expressed as CO2 kilograms equivalent/cubic yard (kg CO2-eq/yd.)

Major investments in fleet and fueling infrastructure, plus information technology and technical services teams, have California-based National Ready Mixed Concrete Co. (NRMCC) set to calculate and seize CO2 reduction opportunities in the Product Stage, thoroughly quantified in the company’s deep EPD library, and the less profiled Construction Process, where mixer fleet fuel consumption is a key carbon data point. CO2 factors in the latter have traditionally been overlooked or not fully appreciated.

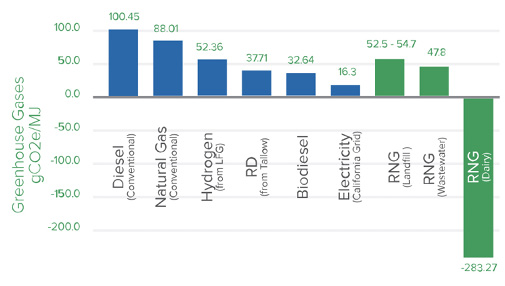

NRMCC is at the forefront of demonstrating the carbon reduction potential of migrating from diesel to compressed natural gas (CNG) as its main fleet fuel. The producer is compounding the lower carbon factor by quickly ramping up one of the largest cement, aggregate and ready mixed fleets to run compressed renewable natural gas (RNG), whose greenhouse gas (GHG) profile—measured on a California Air Resources Board (CARB) scale as grams of CO2 equivalent/megajoule—runs as deep as negative 283.27 versus positive 100.45 for diesel.

A first phase of fleet fuel transition has seen NRMCC order a combined count of 120 vehicles; mixers, dumps and tankers, along with awarding contracts for construction of four CNG/RNG fueling stations. The first station opened last year at the producer’s Vernon plant, a twin alley powerhouse on the edge of downtown Los Angeles sporting 1,100 tons of cementitious storage and 5,000 tons of live aggregate storage.

CARBON COUNTERBALANCE

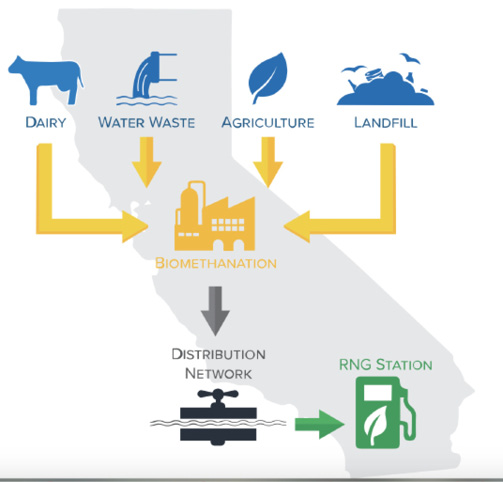

The National Ready Mixed Concrete Association Fleet Benchmarking and Costs Survey indicates one gallon of diesel per delivered yard, adding 40 kg CO2-eq/yd. to the Construction Process carbon tally. NRMCC is demonstrating how that number can become a minus 80 kg CO2/yd. by converting a sizable portion of its diesel-powered mixer and dump/tanker tractor fleet to renewable natural gas. RNG turns the table on the carbon math stigmatizing cement and concrete in this era of greenhouse gas emissions (GHG) inventorying. Measured in diesel gallon equivalents (DGE), the fuel is derived from principal methane-emitting sources: Dairy farms, landfills and wastewater treatment plants. Like conventional natural gas, RNG as a fleet fuel requires significant investment in compressor and station infrastructure—ideally installed within a planned or established truck parking area.

NRMCC sources RNG from White Plains, N.Y. processor, supplier and fueling infrastructure contractor TruStar Energy. An initial contract covers RNG supply for the 120-unit fleet and four station ramp up. Next year, projected delivery will equate to 1.2 million DGE. Between TruStar and other processors/suppliers, present capacity for fuel-grade natural gas from waste methane sources across California amounts to 30 million DGE.

GOLDEN STATE CONVERSIONS

California is home to about 450 CNG mixer trucks and tractors pulling double dump aggregate trailers or cement tankers. Among construction materials operators, NRMCC was not the state’s first out of gate to tap CNG/RNG for fleet fuel, but is moving fastest in vehicle and station deployment. In less than three years—much of the first prone to pandemic disruptions—the producer aims to complete natural gas compressor and fueling stations at four plants. In tandem with that infrastructure build out, it has taken delivery of 89 mixers and 31 two axle tractors, with ten additional tractors ordered for 2022 delivery. The units are all Peterbilt cab and chassis powered with Cummins Westport ISX G engines in 9L and 12L configurations.

Ready Mixed Concrete Co. exhibits with a breakdown of the impact

that renewable natural gas has on enterprise carbon dioxide emissions reduction efforts. Material trucks and mixer trucks running

RNG, processed from dairy farm methane reduces CO2 emissions in

both the product stage and construction phase of any job.

“Our mixer, tanker and dump drivers have logged more than 5 million miles in RNG-fueled trucks to date. There is no other low- or zero-emission technology available that could enable a heavy-duty fleet like ours, running routes from Southern to Central California, to offset the level of greenhouse gas emissions reductions we’ve achieved,” says NRMCC President Steve Lode. “The conversion to RNG also brings value in the overall reduction of embodied carbon in production of custom concrete mix designs—demonstrating a commitment to making our environment a better place one load at a time.”

“The expectation for the first round of CNG/RNG-fueled mixers and tractors has already been met,” notes Director of Operations Sam Hild. Lower carbon footprint aside, “Compressed or renewable natural gas has the extra benefit of price stability over diesel.”

“National Ready Mixed Concrete Company presents another example of how RNG-fueled, near-zero emission trucks can deliver crucial greenhouse gas, carbon dioxide and criteria pollutant emission reductions,” affirms California Natural Gas Vehicle Partnership Vice-Chair and Cummins Inc. Business Development Manager Tom Swenson. “Real and immediate environmental impacts can be made when companies such as NRMCC commit to investing in clean fuel and technology options.” As an alliance of air quality, transportation and energy agencies, vehicle and engine manufacturers, fuel providers, and other stakeholders, he adds, the Partnership is interested in increasing deployment of near-zero emission natural gas vehicles throughout the Golden State.

“Near-zero emission natural gas trucks are readily available technology that can reduce nitrogen oxide emissions by more than 90 percent,” observes Wayne Nastri, executive officer of (California’s) South Coast Air Quality Management District, one of a handful of agencies that provides grants incentivizing fleet upgrades sunsetting older diesel power. “NRMCC’s ability to increase its natural gas fleet is providing immediate air quality benefits.”

A second station is under construction at NRMCC’s Irwindale Plant and scheduled to come on line by year end. Work is scheduled to commence in early 2022 on NRMCC’s Glendale and Santa Clarita plant CNG/RNG fueling infrastructure. Fueling station build contracts have been awarded to both Ozinga Energy (Vernon, Irwindale) and TruStar Energy (Glendale, Santa Clarita).

ACCOUNTING ON A DIME

Beyond kg CO2-eq/yd. or mt snapshots, EPDs prepared according to guidelines of the International Organization for Standardization (ISO)—of which ASTM International is a partner for North America—are necessarily complex. Consequently, preparation of credible, ISO-compliant declarations can be time consuming and expensive.

gas emissions.

NRMCC has approached the RNG fleet fuel program knowing that AEC professionals’ or agency officials’ full recognition of the reduced carbon factor in delivered ready mixed hinges on a) expedited submittal of EPDs for standard or custom concrete mixes; b) supply chain transparency; and, c) digital tools with which technical services staff optimize mix designs best suiting carbon-minded customers or specifiers while meeting all constructability requirements.

NRMCC is the first Los Angeles market ready mixed concrete operator to implement a set of digital applications to streamline EPD preparation. Over the past 20 months, as the Vernon Plant diesel power units gave way to RNG-fueled trucks, the producer has taken an aggressive approach to EPD bandwidth and spontaneous document preparation through a partnership with Climate Earth Inc. of Richmond, Calif. In the process, NRMCC has gone from 11 plants averaging 30 declarations each to an enterprise library approaching 6,000 EPDs—Vernon alone representing more than 1,000.

“Until recently, architectural, engineering and construction professionals have depended on estimates and after-the-fact carbon metrics to design and build reduced carbon projects,” says NRMCC Director of Technical Services John Halverson. “We can now generate immediate, precise environmental and performance metrics for complex concrete mix designs any time in the project cycle. Working with our team, design, engineering and construction professionals can build with confidence and rely on the quality and sustainability of ready-mix concrete for the most demanding reduced carbon projects.”

NRMCC elevates customer experience with Climate Earth’s full CarbonCLARITY Suite, anchored on three applications:

- EPD Generator, to serve customers and project demands by generating fully verified mix specific EPDs in seconds. This technology enables NRMCC to design innovative new mixes to meet requirements for any job, from any company batch plant, while also meeting stringent demands for strength, workability, and durability.

- Project Builder, affording users access from a desktop or smartphone to instantly calculate the high, medium, and low potential carbon impact of any project using verified EPD data, from NRMCC’s store of 6,000 declarations. NRMCC experts then engage with users via the Concrete Designer tool described below to recommend performance-based specifications and mixes that meet all requirements at the lowest carbon impact.

- Concrete Designer, enabling NRMCC experts to engage directly with architects and engineers to refine ready mix requirements for even the most complex jobs while optimizing performance and reducing carbon impact.

“CarbonCLARITY modules allow users to examine options and consider material tradeoffs in the event of a carbon budget. Users may want to focus on global warming potential (kg CO2-eq/yd.) or overall environmental impacts. We have the ability to customize a schedule with verified third party data that is instant and precise,” observes Steve Lode. “This technology investment helps us become the clear leader in meeting the building design community’s urgent need for real time digital environmental data. We have expanded our Technical Services, Sales and Operations teams and, in my opinion, have some of the industry’s best experts on low carbon transportation methods and concrete production.”

“National Ready Mixed Concrete has the expertise and production capacity to serve Los Angeles market demands. CarbonCLARITY Suite reinforces its reputation as a proven innovator with deep commitments to the building design community,” adds Climate Earth CEO Chris Erickson. “The capabilities and expedience NRMCC exhibits through EPD Generator, Project Builder and Concrete Designer, he notes, help the Technical Services team “move customers from prescriptive to performance-based specifications,” a universal quest for ready mixed producers.

“There are hurdles to overcome throughout this process,” Lode concludes. “If you look at our industry in terms of technology, it does not fly at the speed of sound like others—even in terms of online tools. When we started out with CarbonCLARITY, there were limited takers. Now we’re seeing customers turn the corner and respond. The technology and premise are outside of many in the AE community comfort zone, but it’s where we need to go and a place we are proud to lead the market.”